Key Takeaways

- At Reich Construction LLC, we leveraged pre-engineered steel to rebuild Selby on the Bay’s Community Center after a devastating fire.

- The new design is not only fire-resistant but also cost-effective, taking advantage of the scenic views.

- Pre-engineered steel buildings are known for their durability, speed of construction, and cost savings. They can be also customized to meet community needs and withstand natural disasters.

- The project showcases Reich Construction LLC’s expertise in architectural design, engineering, and construction.

Revitalizing Community Spaces with Pre-Engineered Steel

When the beloved community center at Selby on the Bay suffered a tragic fire, it was Reich Construction LLC that stepped in with a solution as resilient as the community’s spirit: a pre-engineered steel building. This wasn’t just about rebuilding what was lost; it was about creating something better, something that would stand the test of time and nature. In this article, we’ll walk through the journey of how the community center was transformed, why steel was the material of choice, and how we at Reich Construction LLC executed the vision with precision and care.

Quick Insight into Selby on the Bay’s New Community Center

The new community center is more than just a building; it’s a beacon of hope and a testament to the power of innovative construction techniques. With a contemporary design that maximizes the picturesque views of the bay, the structure is engineered to serve multiple purposes, from hosting weddings to community gatherings, all within a fire-resistant framework that ensures safety and longevity.

Core Advantages of Pre-Engineered Steel Structures

Pre-engineered steel buildings are not a novelty in the construction world, but their benefits are often understated. These structures are:

- Cost-effective due to their standardized manufacturing process.

- Quick to erect because components are pre-cut, pre-drilled, and ready for assembly.

- Durable, withstanding harsh weather conditions and reducing maintenance costs.

- Flexible in design, accommodating a vast range of architectural styles and purposes.

- Environmentally friendly, as pre-engineered steel is a recyclable material with a minimal carbon footprint.

The Heart of the Community Reborn

We took on the challenge of resurrecting the heart of Selby on the Bay, a community center that had been reduced to ashes. The goal was not only to rebuild but to enhance the community’s experience with a space that was safe, versatile, and visually stunning.

The Historical Significance of Selby on the Bay Community Center

Developed in the 1930s, the community center was more than just a structure; it was a hub of activity, a place where memories were made and traditions were kept alive. From local gatherings to Halloween and Christmas parties, the center had been an integral part of Selby on the Bay’s social fabric. Its loss was deeply felt, but the community was determined to see it rise again.

The Devastating Fire and its Aftermath

“It was a place that was utilized by the community. Unfortunately, there was a fire started by some kids playing on the front porch, and the building was reduced to a pile of burnt-up lumber and ashes,” recounted Martin O’Callaghan, Former Chairman of the Building Committee. The fire highlighted the need for a more fire-resistant structure, one that would safeguard the community’s investment for generations to come.

Choosing a Fire-Resistant Future

Following the fire, the community’s resolve to build a fire-resistant center was clear. “We called Bruno because we wanted a building that wouldn’t burn. We thought concrete and steel would be the best materials,” said William Harding, a member of the Building Committee. This decision led them to us due to our expertise in pre-engineered steel construction.

Meeting the Fire Marshall’s Requirements

The new design had to meet stringent fire safety standards. By designing the building at grade level and choosing pre-engineered steel, the community center would not only have a reduced risk of fire but also avoid the need for a sprinkler system, as per the Fire Marshall’s advice. This strategic choice saved the project a substantial amount of money and time.

Criteria for a Cost-Effective and Safe Design

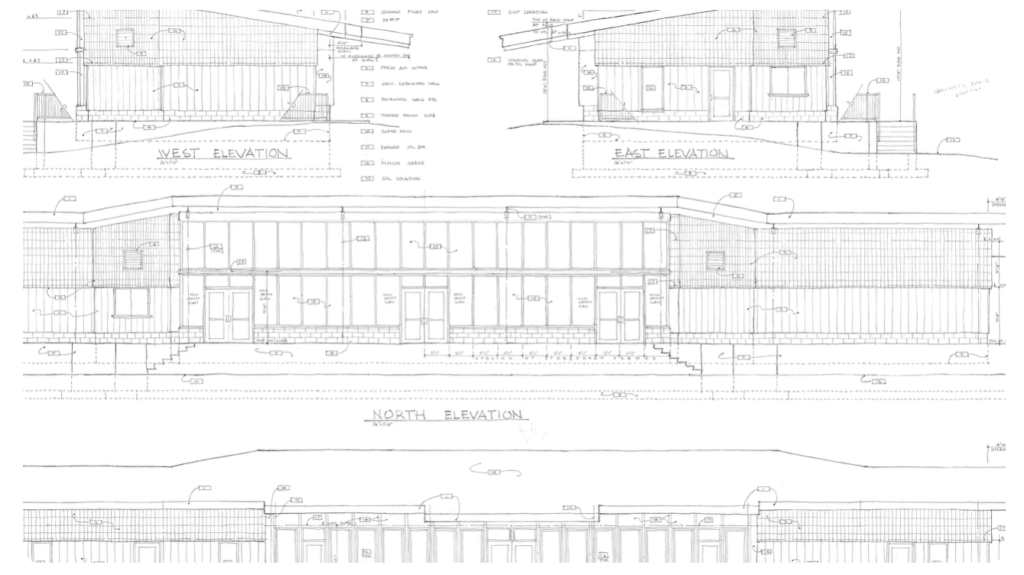

Cost-effectiveness was a key factor in the decision-making process. “They came to me because they believed that a pre-engineered steel building could be more cost-effective. I showed them a design that was much more contemporary, open, and took advantage of the view, while still fitting within the original footprints but offering much more functionality,” explained Bruno Reich, Architect & CEO of Reich Construction LLC.

A Workable Engineering Solution

Understanding that safety and budget were top priorities, we had to find the perfect balance. The design needed to be robust enough to withstand potential hazards, yet economical enough to not strain the community’s finances. This is where our expertise came into play, identifying the most cost-effective materials and construction methods without compromising on safety or quality.

Bruno suggested putting it on a hill and bringing in some dirt.

William Harding, Member, Building Committee

Our approach was straightforward.

According to Reich, “by simply raising the existing grade by four feet, it would satisfy the floodplain requirements, allowing the building to be built at grade level.” So, we went with that.

In fact, by keeping the assembly space at grade level and keeping the main space under maximum floor area, we avoided code requirements for a sprinkler system This improved safety of the occupants and allowed large curtain walls of glass to maximize the incredible view over the water.

We would also use pre-engineered steel, a material with a high melting point, to minimize fire risk. Additionally, the prefabricated nature of steel components meant construction could be completed faster and with fewer labor costs. Most importantly, we worked closely with the local fire marshal and building committee to ensure every aspect of the design met or exceeded fire safety regulations.

By raising the grade instead of making a 2 storey building, we avoided costs for an elevator, a sprinkler system, extensive foundations and other costs saving over $1,000,000.

.

From Ashes to Renewal

With the criteria for safety and cost-effectiveness set, we began the process of bringing the new Selby on the Bay Community Center to life. The new center would be a facility capable of hosting an array of events, with modern amenities and a design that embraced the natural beauty of Selby on the Bay.

Engineering a Raised Foundation: How and Why

Rising from the tragedy, the new community center’s design included a raised grade. This was a strategic move for several reasons.First, it elevated the building above the floodplain, crucial for a site near the water. It also provided an additional layer of protection from any future fires, as flames often spread more slowly upwards.

The Strategic Use of Pre-Engineered Steel: Durability Meets Aesthetics

The choice of pre-engineered steel was deliberate. Not only does pre-engineered steel offer superior fire resistance, but it also provides the structural integrity needed to withstand extreme weather, which is crucial for a building by the bay. Aesthetically, pre-engineered steel allowed for a sleek, modern design with large, open spaces that could be easily adapted for different uses. The material’s versatility gave us the freedom to incorporate large curtain walls, inviting the outside in and offering panoramic views of the bay.

A Return to Service and Celebration

As the steel framework was erected, the community watched with anticipation as their new center took shape. The structure was a symbol of their collective strength, a place where they would once again gather, celebrate, and create memories. With each beam secured and each panel placed, the center was slowly returning to its role as the cornerstone of Chesapeake Bay, Maryland.

The Multifunctionality of the New Center

The new Selby on the Bay Community Center was designed with versatility in mind. It needed to be a space that could accommodate everything from casual community meetings to elegant weddings. The use of flexible space elements meant that the center could transform to suit the occasion, whether it was a festive crab feast or a competition.

This multifunctional approach not only maximized the usability of the center but also ensured that it would be a viable asset for the community for years to come. It was a place designed not just for the now but for the future, adaptable and ready for whatever needs might arise.

Embracing Views and Versatility

“It also made the building more usable, allowing for big open curtain walls to see through the building and take advantage of the incredible view out over the bay, whether for crab feasts, weddings, or even pickleball,” said Reich.

The design we implemented celebrated the center’s location, offering unobstructed views of the Chesapeake Bay that made the space feel open and connected to the surrounding environment.

Showcasing Reich Construction LLC’s Prowess

Throughout the reconstruction of the Selby on the Bay Community Center, our team at Reich Construction LLC showcased the full range of our capabilities. We demonstrated not just our expertise in pre-engineered steel buildings, but also our commitment to delivering a project that resonated with the community’s needs and exceeded their expectations.

The Legacy of Outstanding Builds

With over 40 years in the industry and more than 1500 projects under our belt, we’ve honed our skills and refined our processes to ensure that each project we undertake is a testament to our dedication to excellence. The Selby on the Bay Community Center is just one example of the legacy we’re building, one of resilience, innovation, and community focus.

Services that Lead to Excellence

Our services encompass the entire construction process, from the initial design phase to the final build. We believe in a hands-on approach, where we work closely with our clients to understand their vision and bring it to life. Our team of engineers, architects, and construction professionals are the best in their fields, ensuring that every project is built to the highest standards of quality and safety.

Ensuring Safety Excellence: Accredited Practices from Planning to Completion

We are members of The American Institute of Architects (AIA), Metal Building Contractors and Erectors Association (MBCEA), and U.S. Green Building Council (USGBC). Our comprehensive support spans from concept to construction, ensuring seamless, efficient project lifecycles. We guide and shape our client’s visions into viable plans, aligning with their goals, while adhering to top industry standards for safety and environmental sustainability.

We invite other communities to take inspiration from our story. If you’re facing the challenge of constructing or revitalizing a community space, consider the advantages of pre-engineered steel. With the right team, like Reich Construction LLC, and a shared vision, you too can create a space that embodies the spirit of your community, stands the test of time, and respects the environment. Contact us to learn how we can bring your projects to life.

Frequently Asked Questions (FAQ)

Pre-engineered steel buildings have sparked a revolution in how we approach construction, especially for community spaces like Selby on the Bay’s new community center. They raise questions, and rightly so, about their effectiveness, cost, and impact. Let’s delve into some of the most common inquiries.

1. What Makes Pre-Engineered Steel Fire Resistant?

Pre-engineered steel’s fire resistance is one of its most celebrated qualities. It’s non-combustible and won’t contribute to the spread of a fire. This makes it an ideal choice for community buildings, where safety is paramount. Additionally, the components of a pre-engineered steel building are designed to maintain structural integrity at high temperatures, providing more time for evacuation and firefighting efforts.

2. How Cost-Effective Are Pre-Engineered Steel Structures Compared to Traditional Builds?

When it comes to cost, pre-engineered steel structures often have the upper hand. They are:

- Less labor-intensive to erect due to prefabrication.

- Less wasteful as components are made to resist wind loads, snow loads, and seismic loads better and in a more efficient way.

- Quicker to construct, which translates to reduced labor costs and quicker utilization.

Furthermore, their durability means less spent on maintenance over the building’s life. It’s not just about the initial investment; it’s about long-term savings.

3. What Are the Environmental Benefits of Steel Buildings?

Pre-engineered steel’s environmental benefits are noteworthy. It is 100% recyclable, which means it can be repurposed at the end of its life without losing strength or durability. Moreover, the precision of pre-engineered steel reduces on-site waste. These factors contribute to a smaller carbon footprint and a more sustainable construction process.

4. How Do Steel Buildings Handle Natural Disasters?

Natural disasters test the limits of any structure, but steel buildings are designed to withstand a lot. They can resist high winds, heavy snow, and even seismic activity. Their ductility and strength mean that they bend without breaking, providing better chances of withstanding natural forces.

5. Can Steel Buildings Be Customized for Community Needs?

A resounding yes. Steel buildings offer incredible flexibility in design. Whether it’s for a community center with large open spaces or a library with quiet study nooks, steel can be molded to fit the need. The Selby on the Bay Community Center is a prime example of how a steel structure can be both functional and beautiful, serving the community’s needs while enhancing its surroundings.